WinCan Sewer Inspection Software for Portable Camera Equipment

AI-enhanced, Cloud-Enabled Asset Management Software

Richer Data, Deeper Analysis, Better Decisions

Uncover New Insights from Your Sewer Data.

Imagine a single, integrated application that gives you the power to manage your wastewater resources and assets in real time. With WinCan, you can coordinate team members around high-efficiency workflows, leverage AI to find defects and plan rehab, and visualize complex data with an easy-to-use, map-based interface.

One Platform for All Your Sewer Data

Break out of data silos. WinCan consolidates all your asset data on a single AI-powered platform.

WinCan’s asset-centric approach means you can interpret inspection findings holistically. Whether you’re correlating pipe grade to debris accumulation, understanding root intrusion in terms of surface vegetation, troubleshooting I&I, or establishing asset criticality—WinCan gives you the full picture so you can make smarter decisions about inspection, maintenance and rehab.

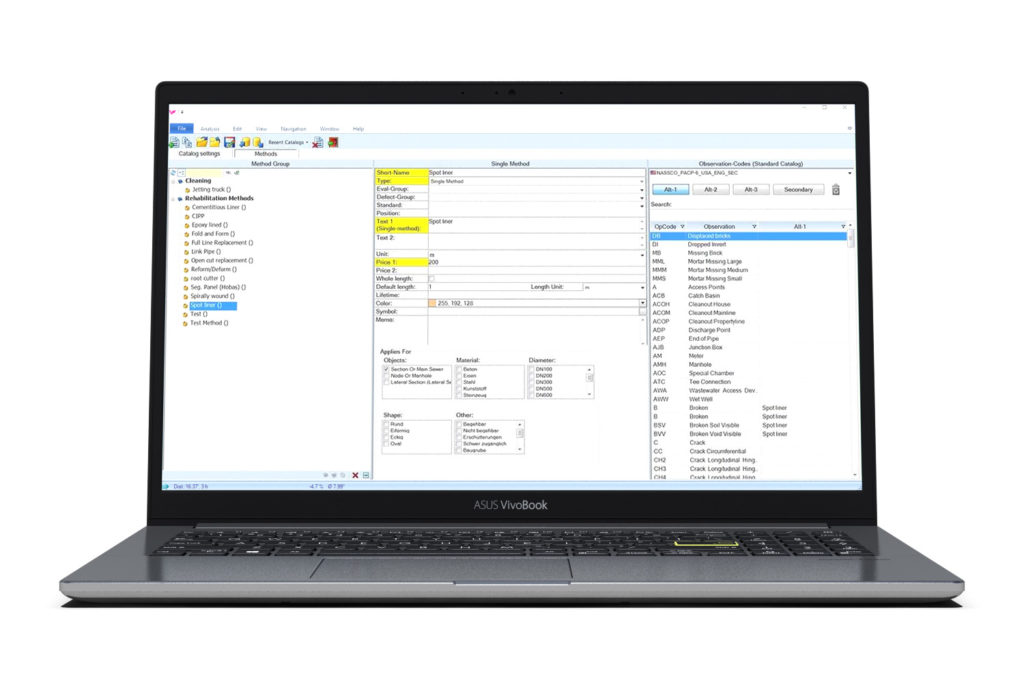

Gather standards-compliant data using one of 50+ available defect catalogs (including PACP/MACP and WRc). Built-in tools streamline code lookup, feature measurement and header prepopulation.

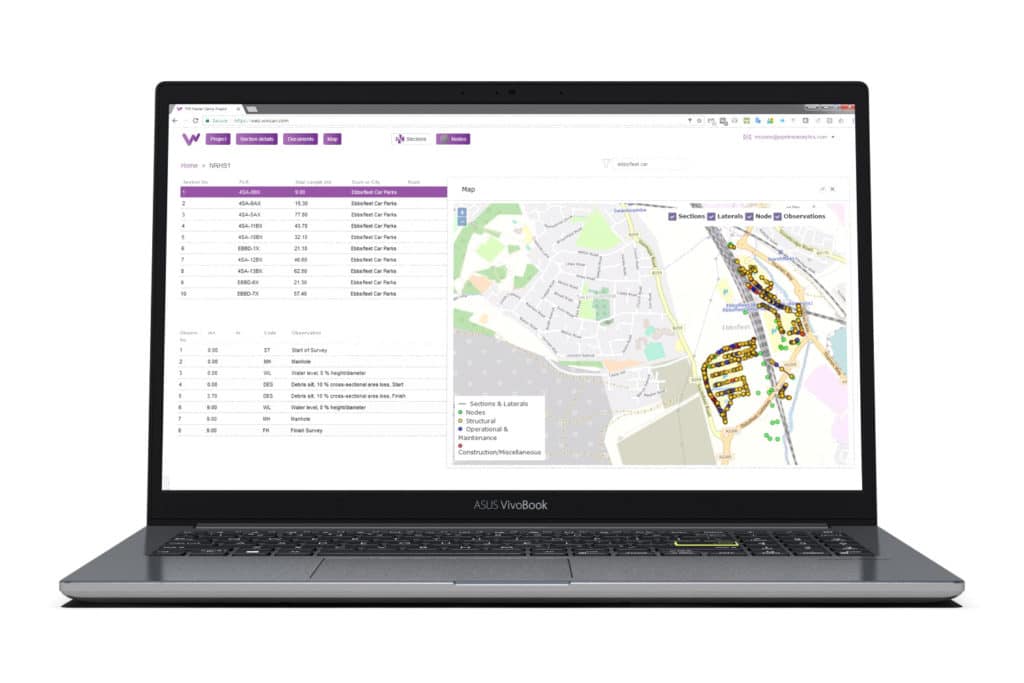

Visualize asset condition system-wide, with granularity down to individual observations. Click and drag to assign work orders, track the progress of your crews, and use visualization tools like heat maps to understand where defects are clustered.

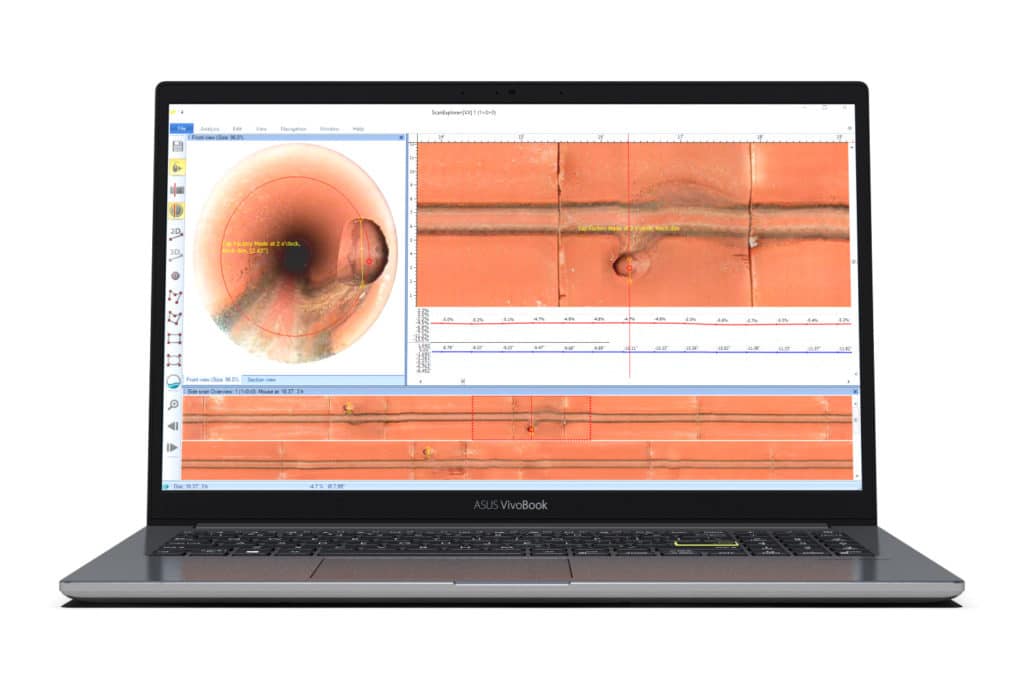

If using laser profiling or side scanning, WinCan has advanced tools for viewing the data and marking up deliverables. Virtual 3D view, pipe geometry creation, feature auto-recognition and heat mapping all help you review scans efficiently and focus your attention where it’s needed.

Using data from XYZ sensors and WinCan’s own image measurement tools, WinCan can build a full model of your collections system. Extend that with geometry from laser scans pipelines (with ROVVER X) and manholes (with Cleverscan), and a “digital twin” of your actual infrastructure begins to emerge.

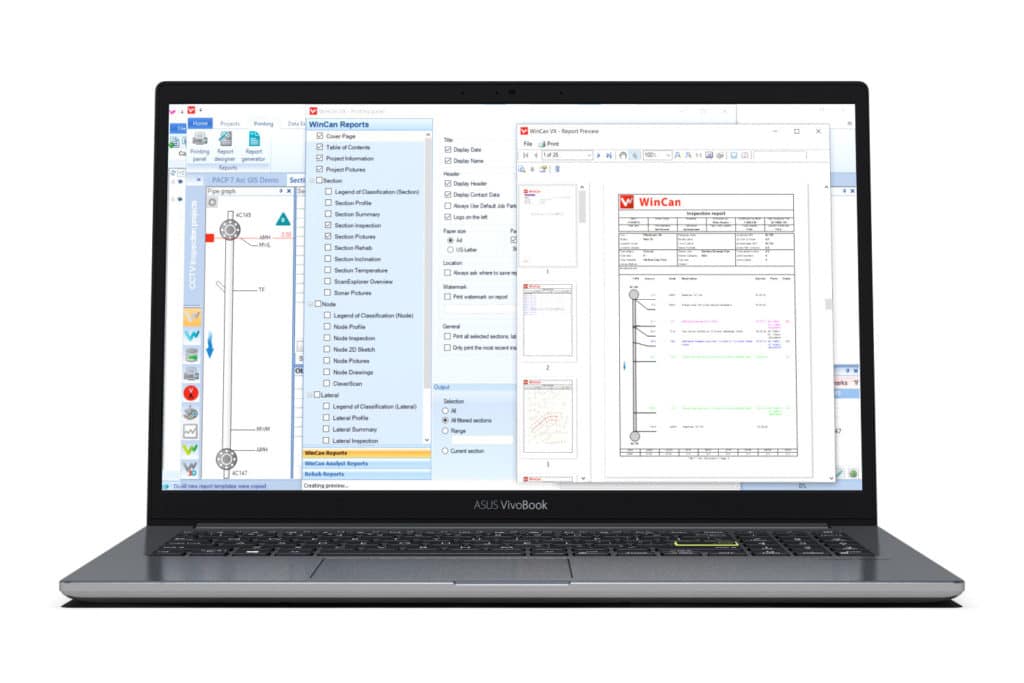

Although WinCan Web allows all stakeholders to interact with source inspection data, sometimes the workflow requires a report. Using modifiable templates, WinCan’s reporting tools allow you to present data for quick comprehension with customized branding.

The goal of sewer inspection is to identify and address maintenance needs. WinCan’s rehab planning module compares collection system condition against cost tables for regionally available rehab methods, and then prepares a detailed rehab plan and budget—saving you days of analysis and guesswork.

Gather standards-compliant data using one of 50+ available defect catalogs (including PACP/MACP and WRc). Built-in tools streamline code lookup, feature measurement and header prepopulation.

Visualize asset condition system-wide, with granularity down to individual observations. Click and drag to assign work orders, track the progress of your crews, and use visualization tools like heat maps to understand where defects are clustered.

If using laser profiling or side scanning, WinCan has advanced tools for viewing the data and marking up deliverables. Virtual 3D view, pipe geometry creation, feature auto-recognition and heat mapping all help you review scans efficiently and focus your attention where it’s needed.

Using data from XYZ sensors and WinCan’s own image measurement tools, WinCan can build a full model of your collections system. Extend that with geometry from laser scans pipelines (with ROVVER X) and manholes (with Cleverscan), and a “digital twin” of your actual infrastructure begins to emerge.

Although WinCan Web allows all stakeholders to interact with source inspection data, sometimes the workflow requires a report. Using modifiable templates, WinCan’s reporting tools allow you to present data for quick comprehension with customized branding.

The goal of sewer inspection is to identify and address maintenance needs. WinCan’s rehab planning module compares collection system condition against cost tables for regionally available rehab methods, and then prepares a detailed rehab plan and budget—saving you days of analysis and guesswork.

Integrated Insight

WinCan connects Every Member of Your Sewer Team.

WinCan Web

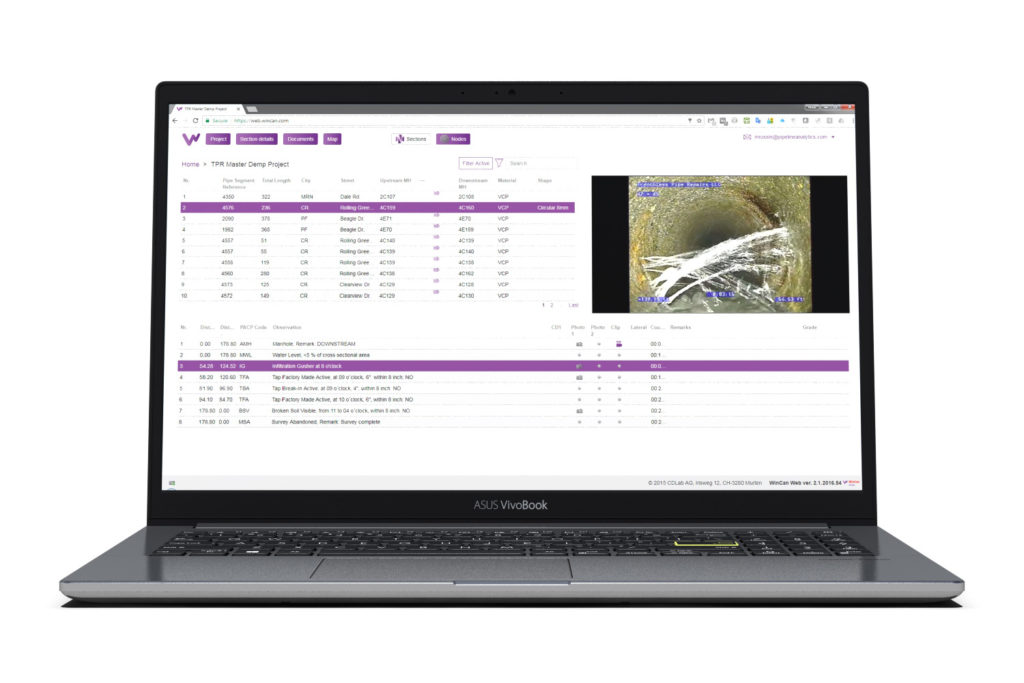

Your data is secure and accessible on the WinCan Web cloud portal. Grant your team real-time access to inspection data—they’ll be able to code, review, edit and analyze inspection datasets using powerful online tools available in any browser-enabled device.

WinCan Workstation

Our desktop app links directly to the cloud for project management. Field inspection personnel and back-office engineers can code data and access powerful filtering and analytical tools—plus enhanced capabilities like 3D modeling, image measurement, scanning and profiling tools, and more.

WinCan Embedded

WinCan’s embedded firmware powers the defect coding and image measurement capabilities of ROVVER X. The Sewerlink app operates the Quickview zoom camera and Jetscan video nozzle, allowing operators to review, assess and annotate footage. And in all cases, inspection data can be transferred directly from the field to WinCan Web.

In the Field, On the Job

Envirosight equipment navigates through sewers, storm drains and laterals, powering power past debris and obstructions. Learn more about the cities, contractors, engineers and DOTs who count on our technology to get the job done, day after day.

“Once we complete a job, what we give to the client at the end is really what separates us from our competitors. They get a map of all of the utilities that we marked on site. If we’re doing a camera inspection, they get the PACP report and in-depth observations. They get pictures and a work order detailing all of the things we did on-site, which is stored digitally so our clients can access it at any time and follow-up with questions.”

Jake Mason | President

Quality Pipe Cleaning

“Because the Envirosight crawler system already has WinCan built in, the data we collect could be uploaded straight to the municipality’s software database.”

Eric Tyler | Vice President

Get up to speed

We did the research so you don’t have to. Here’s the scoop.

Whether you want to gain expertise on crawler technology, defect coding standards, inspection workflow strategies, or a range of other topics, this is the place to start.

5 Things You’re Missing Without PACP

Download NowSewer Maintenance 101

Request YoursAnatomy of a Collection System

Request YoursDigital Workflows Infographic

Download NowDigital Workflows Whitepaper

Download NowKeep Learning

Get Free Resources